Material Change in Heat-Resistant Metallic Materials under High-Temperature Hydrogen Environments

Realizing a decarbonized society requires the use of hydrogen as an energy storage medium and as a raw material in manufacturing. The success of technologies related to hydrogen production, transportation, power generation, internal combustion engines, and hydrogen steelmaking is considered crucial. While there are skeptical opinions about hydrogen technology due to concerns about supply and price, it is expected to become a necessary technology after 2030, requiring problem identification and investigation from now on. High-temperature hydrogen environments of over 600°C are generated in promising high-efficiency hydrogen production methods such as solid oxide electrolysis cells and ammonia decomposition hydrogen combustion gas turbines.

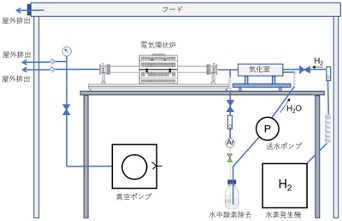

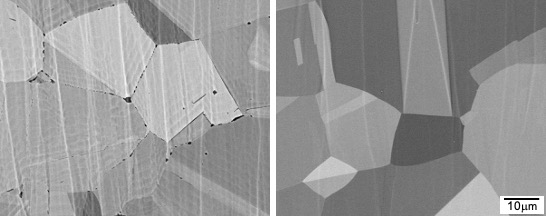

Material damage caused by high-temperature hydrogen environments is called "high-temperature hydrogen damage" and results in decarburization (see Figure 1) and the formation of methane bubbles. This field has been investigated and researched in the oil refining and chemical plant industries for many years, but it does not cover the high-temperature conditions and materials expected in the abovementioned hydrogen environments. Our laboratory has started building heat treatment methods that can maintain high-temperature hydrogen environments for extended periods and has initiated fundamental evaluations on material change behavior in high-temperature hydrogen environments for a wide range of materials, from stainless steel to nickel-based alloys.

(left) inside the sample, (right) near the sample surface