High efficiency of turbines and heat resistant materials

Recently, due to the trend toward decarbonization, there has been growing interest in decarbonized fuel technologies for power generation and aviation applications. However, even if decarbonization is achieved, improving the efficiency of thermal engines remains an important issue for enhancing technological capabilities and cost competitiveness. We will continue to work on research aimed at enhancing the heat resistance and performance of materials that enable increased efficiency in aircraft engines and gas and steam turbine power generation.

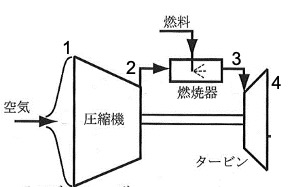

In gas turbine power plants and jet engines (see Figure 6), a high-temperature, high-pressure fluid is created by the compressor (1→2), mixed with fuel, and exploded (2→3), using that energy to rotate the turbine (3→4). The thermal efficiency can be increased by raising the pressure ratio of the compressor and the inlet temperature of the turbine. Therefore, the development of materials that can accommodate improvements in the compressor pressure ratio and increases in turbine inlet temperature is an important challenge.